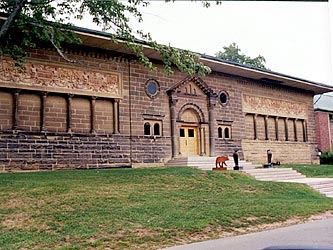

Case Study #2

Restoration of a Heritage Structure

| Problem: Following the appearance of extensive cracking and dislodgement of stone masonry units, PJ Materials Consultants were asked to investigate cause, as well as develop and manage the strategies for the restoration of a 100-year old art gallery and museum. |

|

|

Non-destructive testing revealed that the lime-mortar used to grout the inner core rubble had extensively deteriorated and that the outer wythe was no longer well-bonded. Further investigation also revealed that renovation work carried out in the 1970's had significantly affected, 1) the stability of the masonry, 2) the internal environment, and 3) the way in which the building accommodated movement during extreme changes in temperature. The movement over time had also caused stone columns to become over-loaded and cracked. The major problem was how to restore durability to the structure and stabilize the sandstone masonry walls while allowing movement to occur without causing further damage. |

|

| Solution: A strategy was developed that incorporated the use of special semi-flexible stainless steel masonry ties installed across the full thickness of the masonry walls; the loads were temporarily relieved from the columns, and voids within the inner core rubble were then grouted with a purpose-designed low strength, cellular foam cement grout. Finally, all hard masonry mortar was removed and the masonry joints were re-pointed using a lime-based mortar. On completion of the restoration work - which also included stone masonry unit re-alignment, rebuilding and repair - the columns were re-loaded. |

|

|

|

|

|